Nitrosamine Impurities Analysis

Nitrosamines Testing Services.

Identifying and quantifying trace impurities in a diverse range of materials and marketed products.

Resolian is your trusted partner for Nitrosamine Analysis with nitrosamines testing sefvices.

With a wealth of experience, we excel in identifying and quantifying trace impurities in a diverse range of materials crucial to the pharmaceutical and healthcare sectors worldwide.

We have extensive experience in the analysis of a full range of nitrosamines, including both Low Molecular Weight Nitrosamines and Nitrosamine Drug Substance-Related Impurities (NDSRIs), in APIs, excipients, tablets, creams, solutions and medical devices.

RESOLIAN:

YOUR Nitrosamines Testing Services Partner

We help drug developers manage nitrosamine risk with expert LC‑MS/MS analysis and validated methods.

- Trace-level testing of APIs, excipients, and finished products

- Regulatory-aligned strategies following ICH M7(R1) and other global guidance

- Collaborative support to integrate testing into your development and quality processes

Trusted insight, high-quality data, confident decisions.

Nitrosamines Testing & Analysis

Nitrosamine Drug Substance-Related Impurities (NDSRI) Analysis

Resolian’s team offers tailored solutions, crafting bespoke nitrosamine analysis methods; and to ensure accuracy and reliability, the team designs and conducts extensive false positive testing, employing HRAMS, pH, nitrite and scavenger experiments.

Resolian’s project managers, with many years of experience in nitrosamines testing and analysis, work in partnership with you to understand your individual project needs.

Going beyond routine testing, the team can assist with route cause analysis, offering insights into complex nitrosamine-related challenges.

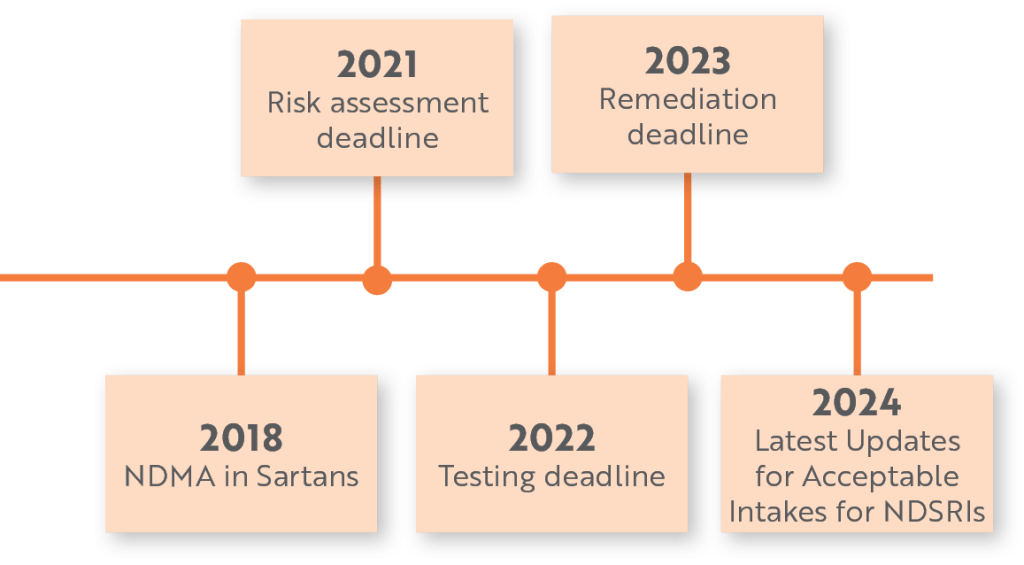

All through, Resolian adheres and stays up to date with the constantly changing regulatory landscape and industry guidelines, including the ICH M7(R1).

“...The high-quality data Resolian delivers helps us make informed decisions with excellent, effective open discussions.“

Resolian Customer

GMP LC-MS/MS Development,

Validation and Batch Release

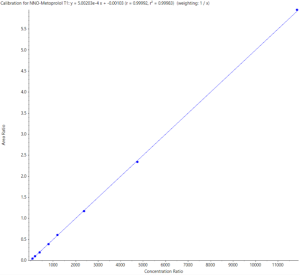

We have developed highly sensitive and robust GMP LC-MS/MS methods suitable for verifying nitrosamine levels in your product for safety risk assessments and batch release.

Each project team within our Nitrosamines group will be led by senior scientists highly experienced in the validation of trace methodologies in accordance with the latest ICH Q2 guidelines, ensuring the methods we develop meet your quality requirements.

Utilising these methods we will support your routine or investigational sample analysis, including GMP batch release, partnering work with you to transfer the methodologies to your QC labs or any combination of the above.

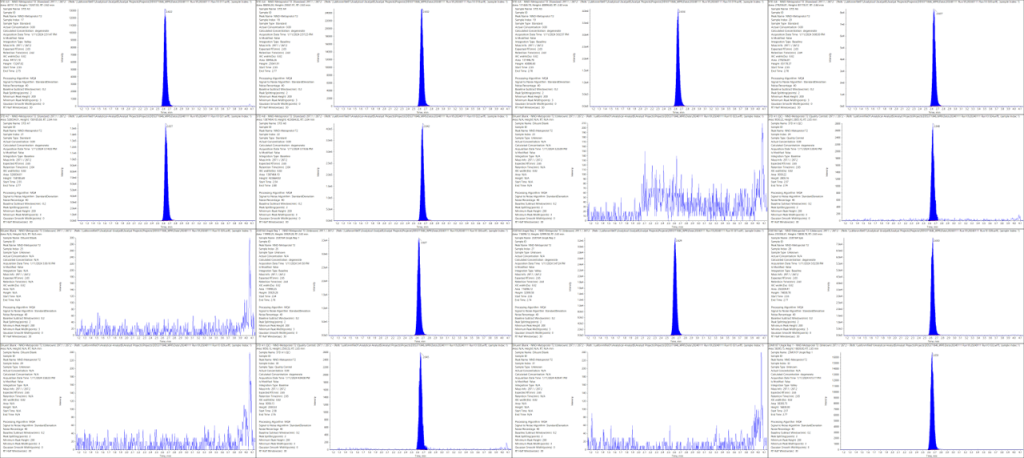

LC-MS/MS is especially suited to the analysis of nitrosamines as most are not readily analyzable using alternative detection techniques. Nitrosamines vary greatly in volatility and most importantly need to be determined at very low levels. LC-MS/MS using a triple quadrupole mass analyser operating in multiple reaction monitoring (MRM) mode, provides the best combination of sensitivity and selectivity.

We work with you to determine the best course of action for your product.

Batch Release

Validation

Maximise Confidence with HRAMS

With the increased molecular size and complexity of NDSRIs, there is an increased opportunity for isobaric impurities to induce false positives.

When a positive result is observed during targeted LC-MS/MS analysis, a more definitive assessment of the component identity may be desired.

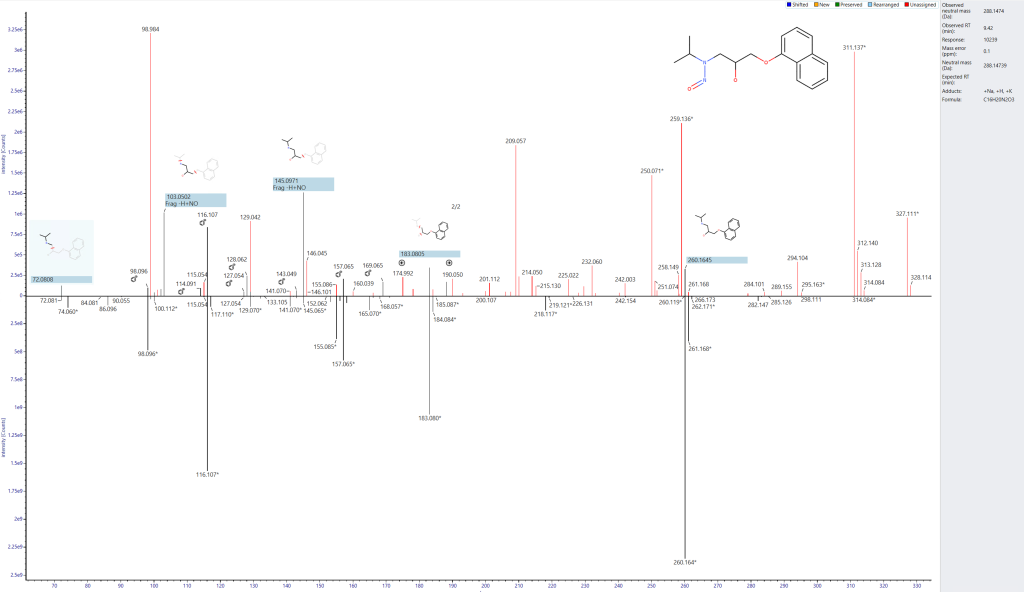

Resolian can utilize a combination of Multi-Dimensional Liquid Chromatography, High Resolution Accurate Mass Spectrometry (HRAMS) and state-of-the-art characterization software, as required, to elucidate the structure of components detected during targeted LC-MS/MS analysis (Figure 1).

Eliminate False Positives

Due to the ubiquity of nitrosation sources, false positive results have been commonplace throughout the history of generic nitrosamine testing. These false positive results have consequently lead to unnecessary financial implications.

At Resolian we specialise in the efficient development of highly selective, tailored methods which differentiate between nitrosamines and structurally similar impurities that would otherwise lead to a false positive.

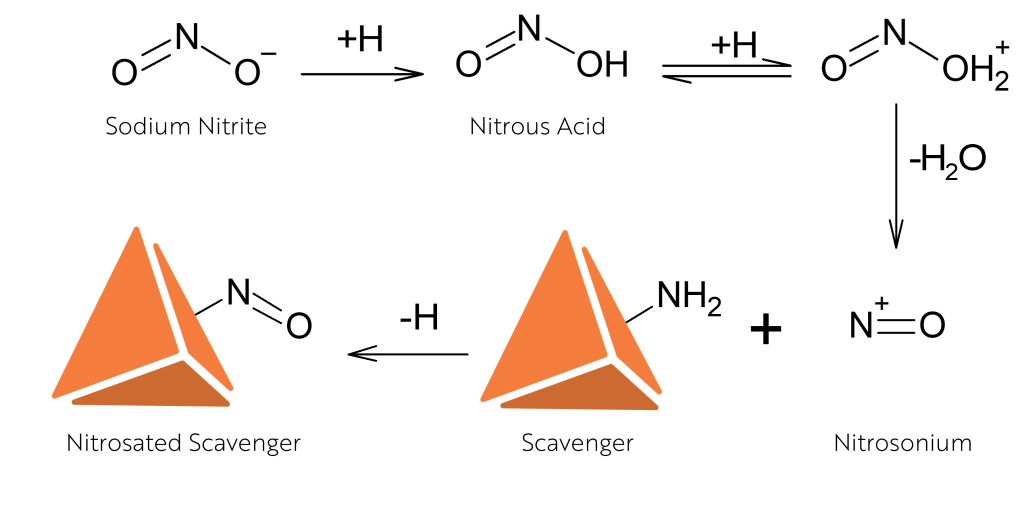

Where nitrosamines are detected, we will provide a package of experiments to verify the source of the observed levels; enabling the development of suitable control strategies for the levels of nitrosamine present and mitigating the risk of unnecessary product removal. An example experimental solution we employ to aid the assessment and prevention of false positives is the utilization of scavengers within the methodology. (Figure 2).

The incorporation of a viable nitrite scavenger at an appropriate stage of the methodolgy can prevent the undesired formation of nitrosamines by intercepting the nitrosation source before it can react with your sample. However, experience is the key to the successful development of a False Positive Assessment Package.

The package will depend upon the nature of the sample and your requirements, as such we encourage a collaborative relationship to efficiently arrive at the desired outcome.

Ready to Advance Your Nitrosamines Testing Strategy?

Your partner in nitrosamine science, testing and compliance.

Resolian brings deep experience in nitrosamine analysis across pharmaceutical materials, formulations and marketed products.

Our experts work collaboratively with development teams to design, validate and execute analytical strategies that deliver high‑confidence nitrosamine data tailored to your needs.